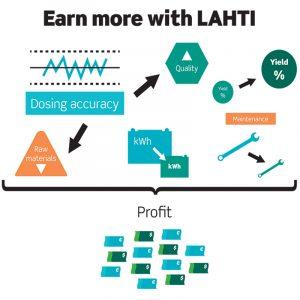

DrymixLAHTI concept provides the best possible dosing technology for dry mix and dry mortar manufacturers. The equipment and the features between the silo cone and packing machine enable customer to make profit substantially better than the peer group utilizing other technologies.

The core of DrymixLAHTI concept is based on four innovative technologies:

DosingLAHTI

WeighingLAHTI

MixingLAHTI

AutomationLAHTI

These together are ensuring superior dynamic dosing accuracy, excellent plant availability with low maintenance costs and homogenous end product with very low scrap rate.

Get shorter payback for your investment – more profit with DrymixLAHTI

- Our own technology fluidization requires less maintenance

- Less waste when using Tamtron reliable weighing and dosing techniques

- Significally less additives consumption due to better dosing accuracy

- Less energy needed

• We are able to design the best possible process for supplying the customers’ needs. DrymixLAHTI technology gives our customers several competitive advantages compared to utilizing other technologies. It has been measured that e.g. waste rate is significantly lower and the plant output yield higher when using DosingLAHTI and Weighing LAHTI. Due to the process performance you don’t either have to use extra amount of expensive additive materials for aiming high quality of end products. Also maintenance rate needed is lower giving better availability for the plant compared to other technologies. All these Drymix LAHTI advantages implemented means that the total investment payback time can be 1 to 2 years shorter than conventionally.

• We are a very experienced, committed and reliable partner. We have supplied worldwide hundreds of demanding industrial bulk materials handling plants, since the foundation of the company 1914. We have built plaster and mortar plants (dry mix plants) and other process technology projects since the 1980’s especially to Asia, Middle East and CIS countries as well as in the Nordics. We have vast experience of operating in different countries and cultures. The over one hundred years of success proves the sustainability and strength of the company both technically and economically. We have been able to renew the company for answering better to our customers’ growing needs.

• DrymixLAHTI can offer the lowest total life time cost for the investment but you need to take us onboard already during planning phase.

• Our Mixing LAHTI technology is specifically developed for Dry Mix & powder materials production.

• We use world class suppliers for all the key process equipment or manufacture them ourselves to ensure the performance and quality.

• AutomationLAHTI system is based on the modern and standard Siemens hardware and Siemens / Windows software platforms. This means excellent local and also remote services for our customer at any time.

The DrymixLAHTI concept takes into account sustainable environmental values.

Lahti Precision is entitled to use the Cleantech Finland® trademark. The equipment, facilities and services provided by the company follow the principles of energy-efficient life cycle and the optimal use of valuable raw materials. Lahti Precision has always been known for its precise metering and weighing equipment – the technologies used are energy efficient and conserve natural resources.

DosingLAHTI Fluidization Technology

We have developed a unique way to transport bulk material using fluidization technology. It differs significantly from all other fluidization solutions on the market and traditional screw solutions.

- Dosing is faster, more accurate, and more repeatable than with traditional techniques

- Better dosing accuracy - higher quality end product and significantly reduced need for expensive additives

- Reduced operating costs - virtually no maintenance required for fluid elements or fluid hoses

- Less waste thanks to reliable weighing and dosing techniques

- Significant energy savings due to the use of gravity in dosing

- The fluid hoses and butterfly valves we use are completely closed - no dust emissions

- A healthier and safer work environment

Contact us

Niko Toimela

Vice President, Sales and Marketing

+358 400 775 582

niko.toimela@lahtiprecision.com

Our unique fluid technology

Check outDosing and mixing systems

Check out

Fescon: fluidized plant beat the traditional "screw plant"

"We couldn't have believed that fluidization-based material transfer and dosing is so completely maintenance-free"

Saveto - Drymix success story in Middle East

Over the past 20 years, Saveto has successfully expanded its business in cooperation with Tamtron.

Technistone: Tamtron's fluid system works perfectly

Tamtron's fluid system solved the filler transport problem

DrymixLAHTI FlexiBatch – flexible low cost plant

DrymixLAHTI FlexiBatch – improved safety with flexible low cost plant