Tamtron (former Lahti Precision) experts noticed about ten years ago that the markets were asking for small capacity plants. It should be quick to deploy and even portable when needed. The light steel structures required by the production process can also be placed in an existing building.

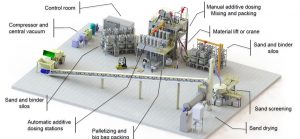

Thus it was created DrymixLAHTI FlexiBatch concept which is able to meet the customer needs when a modern production process needs to be introduced quickly and cost-effectively. The plant includes all major process phases from raw material storing to end product packing and is capable to same quality level as the ordinary DrymixLAHTI plants.

The plant concept is good from occupational safety point of view. It is able to meet occupational safety requirements when all work including the additives’ handling can be done at ground level.

Why DrymixLAHTI FlexiBatch?

- Proven experience with a full range of project types and sizes

- A versatile, modular plant

- High quality products

- Low investment costs, expandable plant

- Can fit into existing buildings; low height (4m – 12m at dosing/mixing section depending plant capacity)

- Easy to operate and maintain

- Shortest project lead time

- Possible to relocate

- Three basic annual capacities 100 kt/a, 50 kt/a and 25 kt/a

Want to know more? Contact us

Niko Toimela

Vice President, Sales and Marketing

+358 400 775 582

niko.toimela@lahtiprecision.com

DrymixLAHTI concept provides the best possible dosing technology for dry mix and dry mortar manufacturers.

More profit with our Drymix concept

Saveto - Drymix success story in Middle East

Over the past 20 years, Saveto has successfully expanded its business in cooperation with Tamtron.