Fluid technology contributes to the efficiency improvement of the production process

Larger plant and system assemblies which are an integral part of weighing and dosing include also typically receiving, transfer and loading of the bulk materials. We have developed our own advanced fluidization technology to ensure uninterrupted material flow when unloading or dosing material from the silos. Our experience of decades as a supplier of weighing and dosing equipment enables us to find the best solutions for fluidization systems and related solutions. The fluidization system can also be delivered to units where there is no weighing at all. Installation is also easy to old structures.

The fluid components restore the fluidity of the material

Funnel flow, rat-holing and accumulation of large material residues in the cone section of the silo are disturbances that often occur when unloading or dosing bulk materials from a silo. They can be however avoided using the right kind of fluidization. The fluid components (fluid plates and cones) restore the fluidity of the material by feeding air that has escaped from the packaged material. This results to a smooth material discharge flow out from the silo. Compared to traditional fluid components, the components we have developed make the material fluidized in the silo evenly until the silo is empty, regardless of the filling level of the silo.

Efficient and energy-friendly fluidization system

Fluid components can also be easily installed in an existing silo or tank. The fluidization system we offer facilitates the flow of material and makes possible a smooth and controlled silo discharge. The system is activated only seconds prior to start of the silo discharge or dosing. Low pressure compressed air is directed to the silo only for the duration of the sequence. The consumption of compressed air in the process is very small, as only the amount of the air removed from the material during compaction is required. Thus, the fluidization system consumes very little amount of energy and no components of the system are wearing at all.

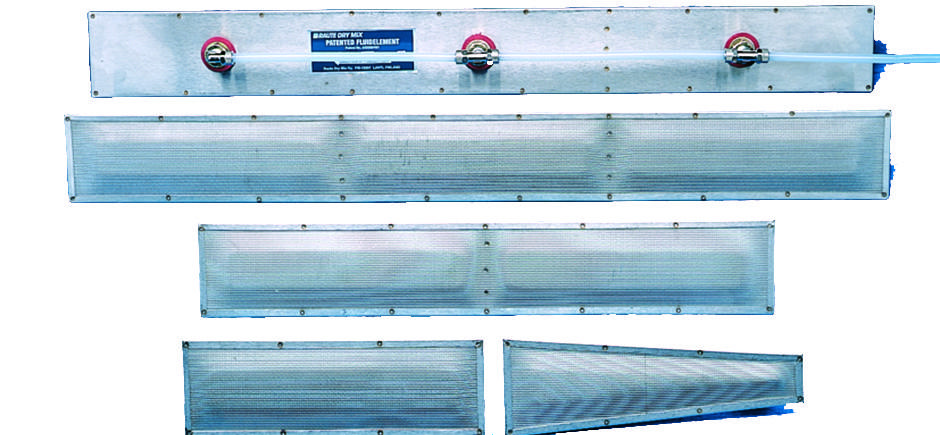

Fluid elements and cones available in standard sizes or custom-made

Our fluid elements are available in two models, FLC and FLA, both available in lengths of 300 mm, 600 mm and 900 mm. By installing elements of different types and sizes in row, the cone of the silo can be covered with fluid elements along its entire length. FLA type fluid cones are also available in standard sizes in six different diameters from D80 / 200 to D250 / 400. If necessary, we are able to manufacture fluid components just for the customer’s structures’ dimensions needed.

- The fluidization system improves the efficiency and trouble-free operation of the production process

- The system is environmentally friendly - because there are no motors, significantly less energy is used

- New technology can also be easily installed in the old process

- Fluid technology ensures easy and fast transfer of fine material

- The need for maintenance of fluid elements or fluid hoses is in practice non-existent

Want to know more? Contact us

Erkki Salo

Sales Manager, Weighing components and spare parts, Finland

+358 40 758 6524

erkki.salo@lahtiprecision.com

Receiving bulk materials and loading systems with fluidization technology

Learn more about our fluidization technologyWeighing and dosing systems

Check out our systems

Yara Eco Oy got a more efficient and ecological production process

Yara Eco Oy's largest fly ash recycling plant in the Nordic countries, operating in Nokia, can handle up to 130,000 tonnes of ash annually. Tamtron has supplied Nokia's plant with fluid dosing equipment for fly ash silos.

Technistone: Tamtron's fluid system works perfectly

Tamtron's fluid system solved the filler transport problem

Fescon: fluidized plant beat the traditional "screw plant"

"We couldn't have believed that fluidization-based material transfer and dosing is so completely maintenance-free"