Does inventory management work in your company in such a way that human resources are not spent on taking care of it? Is there room for improvement in the operation of your warehouse or the management of related data? Does making changes seem laborious and inconvenient? Do you want the information about your product to be traceable and available quickly and efficiently at your disposal?

With the help of Tamtron Precision’s solutions, you can improve your inventory management and get transparency and traceability for managing mass-based material flows in your production facility. Our digital mScales weighing service automates functions, saving energy and time and reducing material waste. Read more about how all this is possible.

The information generated in the process for efficient use

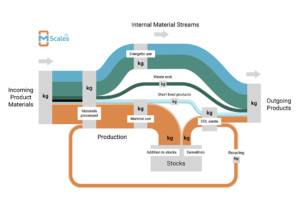

In its simplest form, the main flow of materials in a production plant is relatively straightforward, consisting of, for example, incoming weighing before storage. In the process, raw materials and other materials are brought in to be weighed and dosed according to the specified recipe, resulting in a product being transferred to, e.g., the final product warehouse. Measuring the material entering the plant and the product leaving it is straightforward. However, the process can remain a “grey area” without a warehouse management system that collects data.

More information is constantly needed, and fortunately, it is also available. Our warehouse management solution collects data from the process stages of weighing or dosing. The collected information brings transparency and traceability to the operation of the overall process. With the help of enriched data, the functions of the production plant can also be planned and developed even more efficiently.

Availability in good condition with the help of warehouse management

Keeping raw materials in silos or warehouses longer than needed is not a good idea because it ties up capital. On the other hand, raw materials or materials to be added to the process must stay supplied because supply reliability is a crucial factor affecting customer satisfaction. The materials used in the process may also have a specific shelf life, determining how long they can be stored in the warehouse. Effective inventory management is essential for optimal stock turnover.

With the help of highly accurate weighing equipment and the mScales warehouse management module, raw materials, additives, and circulation are brought to the right level. This way, material orders can occur just in time (JIT).

With automation, you can completely outsource operational functions related to supply chains separate from the production unit to a third party. Thus, a home call/purchase order proposal is automatically sent to the interested party for approval when the material reaches the set alarm limit. And this does not require logging into the order system. Automation also brings other benefits when various facility functionality permits (e.g., driver loading permits) can be issued from the system without separate equipment and procedures.

Better traceability and more transparency

In many industries today, information about products and their composition is needed. This need is constantly growing. Raw material producers or other actors who use different materials in their processes need information to indicate the origin and composition of the product, to optimize material flows and to ensure product quality.

The information generated during the process is important, because it allows the quality of the product to be monitored and operations to be planned more efficiently. With our solutions, the product can also be traced back easily: what is the origin of the raw material, who is the supplier and how much of it has been delivered to the warehouse in each batch. Traceability is useful for manufacturers who need data on the origin of raw materials to document or show their customers, for example in terms of responsibility.

Savings in the use of material, energy, time and human resources

Our warehouse management service, combined with an optimally functioning weighing and dosing solution, saves, among other things, raw materials, energy, time, and human resources.

Accurate information about the materials fed into the process is essential for optimizing the efficiency of raw materials. On the other hand, a precisely functioning system guarantees a product of consistent quality, which reduces off-spec production and thus minimizes the waste of raw materials, energy, and time. With automation, the risk of human errors in the process is reduced, and human resources can be transferred, for example, to excellent customer service work. A high-quality and consistent product also directly connects to the customer experience and the brand image created by your company.

Tamtron Precision – experienced and comprehensive

Our experience with weighing and dosing systems and our knowledge of various dry bulk materials are excellent for high-quality production process planning. A weighing and dosing system optimally serves your needs and creates a solid foundation. The digital mScales weighing service connected to the system takes your process to a new level. With it, you can quickly and reliably access data generated from mass-based material flows and up-to-date inventory balances for you and your business systems.

You can connect our inventory management solution to most operational plant systems. You can also access the benefits through modernizations or new system deliveries. You get the most help from the mScales weighing service when we get to be more comprehensively involved in the system’s design. In this way, we can more flexibly add other value-producing features.

The first step is, of course, the most important. Contact us if you need efficiency and transparency in your production and traceability in your product. We would be happy to explain your situation and more about weighing and dosing systems in different industries and our planned mScales weighing service with modules. Let’s find together the best solution for your needs.

The article’s author is Juha Immonen, the sales manager responsible for our weighing and dosing systems. He has years of multidisciplinary experience delivering larger systems to our international customers in various industries.

Want to know more? Contact us

Juha Immonen

Sales Manager, Dosing and Weighing systems

+358 50 370 4221

juha.immonen@lahtiprecision.com

Get to know our bulk material handling systems

Weighing, dosing and mixing systemsEfficient and reliable transport of bulk materials

Receiving, transferring and loading of dry bulk materials

Accurate dosing and mixing of granular material into the liquid

From bulk material to a liquid mixture of uniform quality - an efficient slurry mixing system with a complete solution

Download the guide to the design of scales and weighing systems

We produced a guide that provides designers and those responsible for procuring a weighing system with information on how to modernize weighing systems and get the most out of them for the benefit of your business.

Bulk material dosing devices for industrial processes

Bulk material dosing processes