Lahti Precision has a long history of implementing mixing solutions for various industries. Due to the increased demand for battery metal applications, we have further developed our concepts to be able to match the needs to this industry as well.

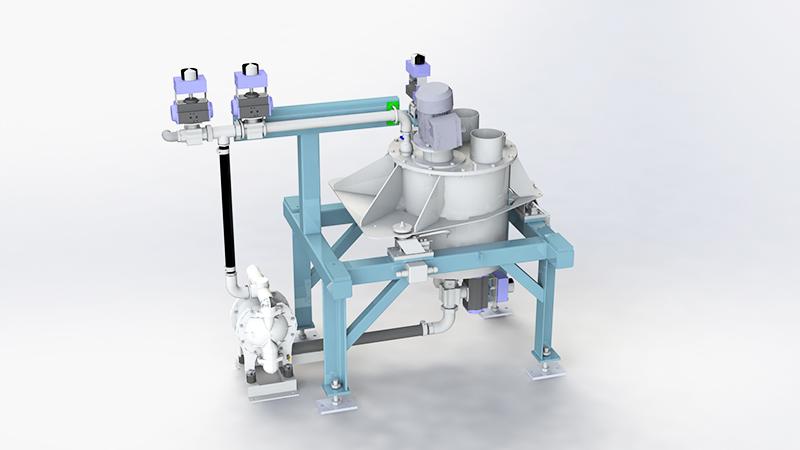

In the battery metal industry, there is quite often a need to add materials (e.g. lithium, nickel, cobalt) to the process either as a main component or as an additional feed. We can offer flexible solutions, for example, to integrate the handling of big bags directly into the tank, by mixing and feeding the media into the process pipeline.

The system is modular and flexible – if you need to change capacity, change materials or resize big bags. The concept can be modified afterwards according to possible changes in the manufacturing process. The devices can be used for handling battery metals, black mass and precursor applications. We also have experience in slurry treatment.

Our equipment is designed according to the strict material requirements of the industry. We can offer our equipment as standalone units with our own PLC controllers and electrical equipment. Equipment can be controlled by DCS or as hybrid version according to customer needs. If necessary, we can also design devices that comply with ATEX regulations.

If you are in the design phase of a material handling project, piloting a new process, or already have a facility where it is necessary to introduce another material supply line or make other changes to an existing main process, our knowledge and flexibility are at your disposal!

The author of the article is our technology director Janne Kousa. He is responsible for the development and design of our company’s key technologies.

Want to know more? Contact us

Janne Kousa

Vice President, Technology and Engineering

+358 40 8604 501

janne.kousa@lahtiprecision.com

Dosing in battery metals’ production process

Strong knowledge of the properties of battery raw materials and experience in their handling and dosing technologies ensures an efficient and reliable production process.

Solid experience has also been harnessed for the needs of the battery industry

The concept we have designed for the needs of the battery industry emphasizes in particular that valuable materials can be efficiently utilized by automating the handling of big bags.

Lahti Precision supplies MixingLAHTI solutions for dry bulk materials’ mixing and for wet mixing.

Learn more about our solutionsDownload the guide to battery industry’s weighing and dosing solutions

In this guide, we tell you about the factors to consider when choosing weighing or dosing solutions for the battery industry.

Read more